Flexible Hanger

(1) Frequency: 5 - 13 Hz

(2) Withstand a continuous acceleration of 1.5g under maximum load.

(3) Deformation in all directions: ±10 mm

(4) Adjustable distance between mounting points: ±50 mm

(5) Operating temperature: -70℃-600℃

(6) Thermal conductivity:< 0.02 (equipped with nano-aerogel felt insulation pads, withstanding temperatures up to 1000°C)

Hope Great can offer a noise and vibration reduction solution based on the layout diagram of the marine engine exhaust system. The flexible hanger, composed of silicone rubber, nitrile rubber, metal components, and insulating pads, can effectively reduce vibration and noise, achieving a reduction of 8 dB(A) to 10dB(A) across frequency ranges from 63 Hz to 4000 Hz.

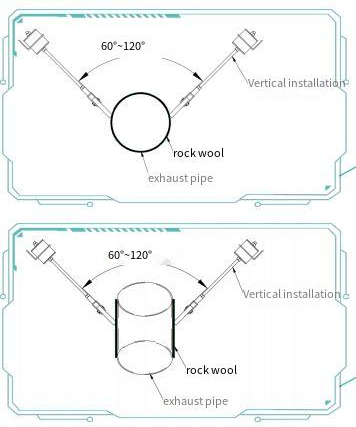

According to the weight of the pipeline and the vibration frequency, we use fixed support points and flexible support points to achieve the best noise and vibration reduction effect. Fixed support points bear static and dynamic forces and determine the direction of pipeline expansion in the exhaust system while flexible support points can control and absorb the displacement caused by the thermal expansion of the pipeline due to changes in exhaust temperature and the displacement caused by structural sway.

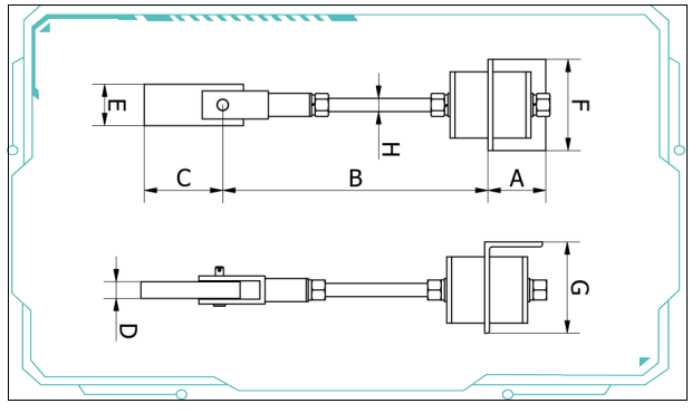

Dimension

Installation Node Diagram of Flexible Hanger

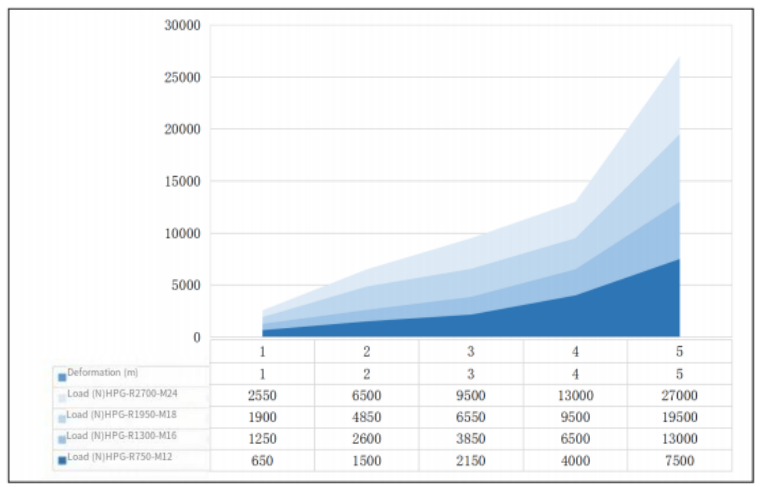

Characteristic Curve

English

English 简体中文

简体中文